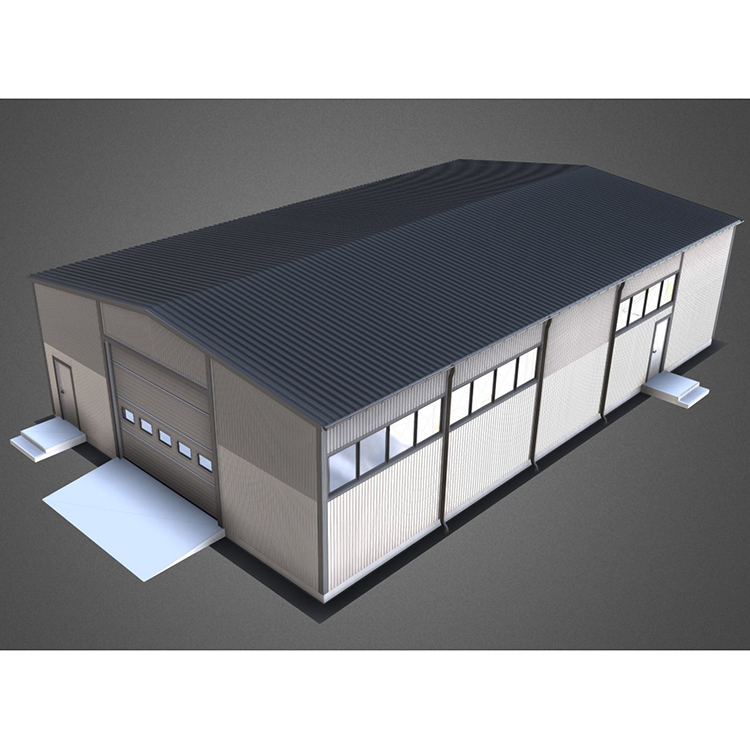

2019 High quality steel structure building warehouse workshop hangar commerical and farm buildings

Our company puts emphasis about the administration, the introduction of talented staff, along with the construction of employees building, seeking hard to boost the standard and liability consciousness of staff members members. Our business successfully attained IS9001 Certification and European CE Certification of 2019 High quality steel structure building warehouse workshop hangar commerical and farm buildings, Our clientele mainly distributed within the North America, Africa and Eastern Europe. we are able to supply premium quality goods with the incredibly aggressive price tag.

Our company puts emphasis about the administration, the introduction of talented staff, along with the construction of employees building, seeking hard to boost the standard and liability consciousness of staff members members. Our business successfully attained IS9001 Certification and European CE Certification of , As an experienced manufacturer we also accept customized order and we could make it the same as your picture or sample specification. The main goal of our company is to live a satisfactory memory to all the customers, and establish a long term business relationship with buyers and users all over the world.

Benefits Of Using steel structure hangar

Fast, easy and cost-effective construction

Thermal insulation and acoustical insulation

Excellent resistance to harsh weather conditions

It is able to create large spans

Environmentally friendly

It can be easily adapted to future uses

Long life span of steel frame

It can be customized to meet your project’s specifications.

Technical Features

The structural steel has a small cross-sectional dimension, which can create useful spaces for buildings, reduce building height and have a better appearance.

The light steel frame has good rigidity and light weight. The steel beams and columns can be assembled, making it easy to fabricate, transport and install.

The amount of steel used to construct light steel frame building is only 1/5-1/10 of common steel structure, thus it is an economical and reliable option.

Applications

It is an ideal solution to erect light duty industrial buildings, such as workshops, warehouses, sheds and storage. The scope of application includes:

The building span is 9-24m, and column height is 4.5-9m. The roof load is small.

This steel structure is suitable for factories where there are overhead cranes designed for light duty and moderate service, or no cranes inside the facility.

When the building span does not exceed 15m, and column height does not exceed 6m, the roof frame beam should be in the form of an equal-section frame. Otherwise, it should be variable section frame. The variable-section steel frame has reasonable force and also saves materials. However, it is not as convenient as the equal-section frame in terms of fabrication and structural connection.

Steel Structure Design And Main Components

steel structure hangar building uses steel as the primary structural element, mainly including steel columns, steel beams, purlins, bracing system and building envelope. It is usually custom designed and constructed to your requirements.

Primary structure: steel columns, steel beams, wind-resistant columns and runway beams. The main material is Q235B or Q345B. The column and beam generally use H-beam steel or C channel steel. The runway beams are used to support overhead crane system, so they are generally installed in the upper part of the factory.

Secondary structure: purlins, bracing systems. C-shaped purlins are commonly used to support wall and roof panels. While the Z-shaped purlins are ideal for large slope roof. The thickness of C-shaped purlins is 2.5mm or 3mm. The horizontal and vertical bracing systems are aimed for overall stability of the building.

Envelope material: color steel tile and sandwich panel. The thickness of commonly used color steel tile is below 0.8mm. While the thickness of sandwich panel can be 50mm, 75mm, 100mm or 150mm. In addition, the roof can be designed with color steel tile, insulation cotton and steel mesh for improved insulation.

In order to save energy as well as improve indoor lighting, the lighting panels are generally added to the roof.

Light steel frame construction

Single span, double span, multi-span

Overhead crane and runway beam are available

Examples Of steel structure hangar For Your Reference

steel structure hangar workshop

It takes the form of light single-span steel frame. A 20 ton overhead crane designed for moderate service will be installed inside the building. Other types of light duty overhead cranes are available for you to choose from.

The roof is designed with organized drainage for simple and better facade effect. It uses polyurethane roof panel as well as self-cleaning panel to reduce the ash accumulation and keep the roof clean.

The wall uses polyurethane wall panel, which has excellent heat and sound insulation.

The building has large span, better appearance, excellent bearing capacity and fast drainage. It is easy and fast to erect.

steel structure hangar warehouse

It is ideal for light warehousing. The steel warehouses can be either large or small.

Light weight galvanized steel structure

The steel is coated with a protective zinc to prevent it from rusting and corroding, thus the galvanized steel structure building has longer maintenance-free service life than an ordinary steel frame building. The thickness of coating can be varied to suit a range of environments.

Multi-storey steel frame building

The primary structure uses steel structure hangar frame. The building floor uses a combined form with steel structure and concrete.

The roof panel uses profiled steel plate, and the wall uses polyurethane wall panel.

Choosing The Right Type For Your Building

The steel structure hangar can be designed into any size and shape on requests. There are several factors to consider when choosing a steel frame construction for your building.

The building length – the overall length of the building is depending on your requirements.

Column spacing – it can be 6m, 7.5m, 9m and 12m.

Span – it is generally in a range of 9m to 36m. When you require a large span, we can design a double span or multi-span based on your requirements.

Height – it is usually 4.5-9m when there are no cranes inside the facility. However, if you want to install an overhead crane, the height is determined by the required crane specifications.

Overhead crane and runway system – if one or more overhead cranes will be installed inside your building, you should specify the crane model, capacity, lifting height, work duty, runway length and so on.

Additional requirements, such as wall and roof insulation.