China H-beam construction prefab industrial steel structure hangar storage warehouse shed

Wide Application Of Steel Structural Shed

The steel structure can be found many uses in both industrial and non-industrial sectors, such as manufacturing, agriculture and civil uses.

Workshop: steel structure workshop is the top option for industrial uses, and it can be used for various manufacturing, repairing and assembly lines. This type of building form will save much money for clients in contrast to concrete building.

Warehouse: steel structure warehouse is an ideal solution for potential users to store goods. It will save much construction time and cost.

Car shed: it is an easy and quick way to build shed for cars. This building form can be seen in numerous civil uses.

Steel Structure Shed Design

The steel structure shed is a cost-effective option for overhead travelling crane users who are thinking about building their own facilities. The industrial shed steel structure will be custom designed and built in accordance with client’s requirements, such as the steel structure building dimension, seismic rating and the rated load of overhead crane.

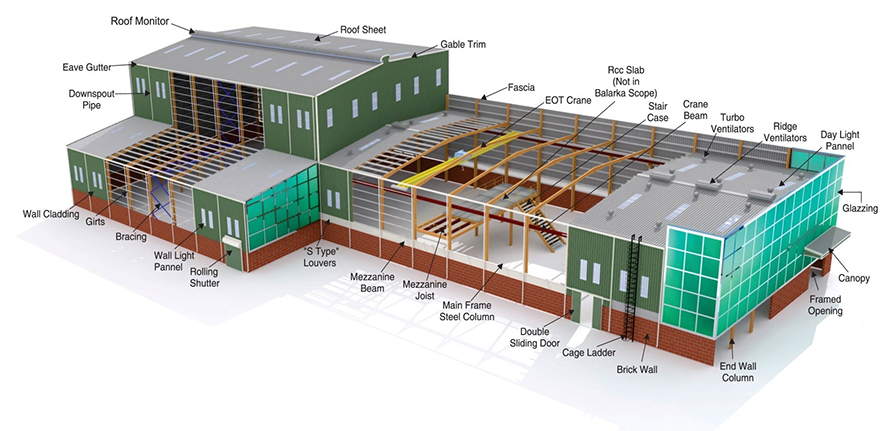

Generally, steel columns and beams constitute the main structure of steel shed buildings, and they are usually made of Q345B steel materials. For overhead crane beam, Q345B H section beam is also used. These steel fame shed components are painted three layers.

The secondary structure mainly consists of wall and roof purling, panels and bracing system. The roof horizontal bracing and wall column cross bracing systems adopt angle steel. The wall and roof panels are available in single color sheet and sandwich panel, and the purling uses C section or Z section.

All components of steel shed structure are connected by high strength bolts. Other structures such as doors, windows, roof gutter and rain spout are customized according to the practical needs of customers. If you have any need for the design of steel structure shed, contact us online now.

The Advantages Of Building A Steel Shed

Wide application: the steel structure is suitable for constructing both single-story and multi-storey buildings, workshops, warehouses, industrial plants, storage sheds and so on.

Quick and easy construction process: the prefab steel structure buildings will greatly shorten the construction period as all components will be prefabricated in the factory and then delivered to the construction site to be assembled.

High strength and long service life: the structural steel provides longer span and stronger cantilevers, and the steel shed frame design is done according to wind and snow loading in the local area, making it strong enough to withstand severe environments, such as strong wind, snow and earthquake. Besides, the steel structure shed requires little maintenance.

Reasonable cost: it is one of the strong points of steel structure, making it popular among overhead bridge crane users who intend to build a steel frame shed. The steel structure shed kits have light dead weight, so the construction cost can be reduced. In a word, the steel structure shed is an economical substitute to concrete buildings.

Environmental protection: the steel materials can be recycled, thus they are harmless to the environment.

Customized Steel Sheds For Sale

The steel structure sheds can be constructed into any shape and size according to customer’s requirements. They can also call for light steel structure or heavy steel structure for sheds. This building form can be extensively used in many different fields, from industrial usage such as steel industrial shed, agricultural usage like steel farm shed to civil usage such as steel car shed. This building form will save a great deal of time and money for clients.

Installation Process

All components will be prefabricated in steel structure factory and then assembled at the construction site, which bring about easy and quick installation process. The installation process mainly includes:

Preparation before installation: to prepare the installation plan and organize the steel shed construction; to check the steel structure members and arrange them in installation sequence.

Primary and secondary erection: this process mainly includes the installation of steel columns, beams, purling, bracing system, and beam end walls.

Other components: to install other accessories, such as roof and wall panels, doors and windows.

Some safety precautions should be taken during installation process so as to ensure a smooth installation progress as well as the safety of workers. For example, any worker entering into the construction site must wear a helmet. The construction machines should be inspected on a regular basis to make sure they are in good working conditions, especially the wire ropes and safety belts. In addition, some protection measures should be taken to prevent damage to steel structure in the installation process.we will provide steel shed drawing to guide steel structure shed installation.