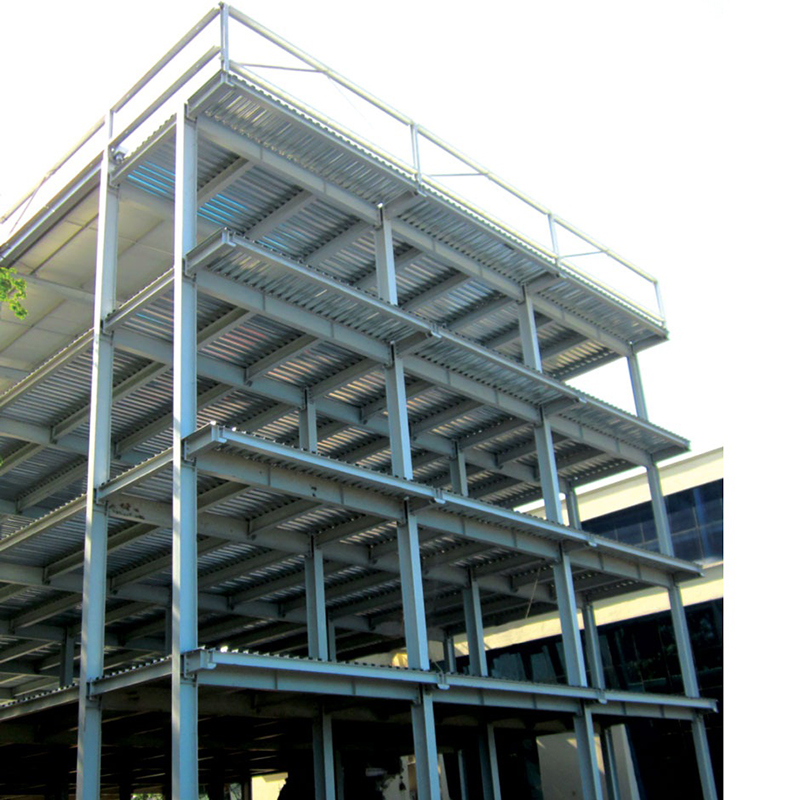

Factory making Structural Steel H Beam - 3D Modular Prefabricated Steel Structure Residential Building – Hongji Shunda

Factory making Structural Steel H Beam - 3D Modular Prefabricated Steel Structure Residential Building – Hongji Shunda Detail:

1、 When transporting and storing steel structure in winter, it is necessary to take anti-skid measures.The garden for component stacking must be flat and solid without water pit and ground freezing.The levelness of components must be guaranteed when the components of uniform type are stacked, and the cushion block must be on the uniform lead line to prevent the components from slipping.

2、 Before the installation of steel structure engineering, in addition to the general inspection, the quality of components must be re inspected in detail according to the negative temperature conditions.If the deviation is greater than the specified value and affects the installation quality, repair and correction must be carried out on the ground. Lifting and installation can only be carried out according to the preset standards.

3、 When the steel cable for binding and lifting steel components is in direct contact with the hook, anti-skid spacer shall be added.All the gusset plates lifted at the same time with the components, the hanging ladder used by the installation personnel, the clamps and ropes for calibration must be firmly bound.When directly using the lifting ring and lifting lug to lift the component, it is necessary to check whether the adjacent weld of the lifting ring and lifting lug is damaged.

4、 When installing components under negative temperature, the installation sequence chart of steel members shall be prepared, and the installation shall be carried out in strict accordance with the regulations.On the plane, it should be installed from the center of the building to the surrounding gradually, and on the facade, it should be installed from the bottom to the top one by one.

5、 Welding process shall be prepared for welding of steel structure.After the first floor member of a column is installed, the bolt connection is corrected and the weld shrinkage is reserved, the welding is symmetrically extended from the center of the structure to the surrounding.It is forbidden to weld the outer ring of the structure to the center, and the two ends of a component shall not be welded at the same time.

6、 If there is snow, ice and condensation on the component, it shall be cleaned before installation, but the coating shall not be damaged.

7、 Special machines and tools for installation of steel structure under negative temperature shall be inspected according to negative temperature requirements.

8、 When the steel structure is installed under negative temperature, the column, main beam, support and other large components should be corrected immediately after installation. After correction, they should be fixed permanently.The components installed on the same day should form a space stability system to ensure the installation quality and structural safety of the steel structure.

9、 When installing the high strength bolt joint, the friction surface of the component must be clean, and there must be no snow, ice, rain, soil, oil and other dirt.

10、 During the installation of multi-storey steel structure, the load stacked on the floor must be limited, and the weight of live load, snow and ice shall not exceed the bearing capacity of steel beam and floor.

11、 Before stud welding, parameters such as welding current and welding time should be calibrated according to the value of negative temperature to ensure the welding quality of stud under negative temperature.

Product detail pictures:

Related Product Guide:

Bauhaus architecture and design from A to Z dezeen-logo dezeen-logo | Affordable Steel Buildings

Bridge replacement work begins on vital trucking route between Lee, Lenox Dale | The Berkshire Eagle | Affordable Steel Buildings

We believe in: Innovation is our soul and spirit. Quality is our life. Shopper need is our God for Factory making Structural Steel H Beam - 3D Modular Prefabricated Steel Structure Residential Building – Hongji Shunda , The product will supply to all over the world, such as: Russia , Istanbul , Myanmar , Now we have a dedicated and aggressive sales team, and many branches, catering to our main customers. We have been looking for long-term business partnerships, and ensure our suppliers that they will undoubtedly benefit in both short and long run.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.