Factory Promotional Light Steel Structure Building - Galvanized Wide Span Light Steel Frame Storage Warehouse Workshop Shed – Hongji Shunda

Factory Promotional Light Steel Structure Building - Galvanized Wide Span Light Steel Frame Storage Warehouse Workshop Shed – Hongji Shunda Detail:

Steel Structure Sheds – A Prevailing Option For Your Facility

For some potential users of overhead traveling crane who do not have pre-existing buildings to support the crane or rent the facilities but look for building their own sheds, the structural steel shed can be an economical and efficient solution. Here are some reasons why it should be a prevailing option to build your shed.

Quick and flexible assembly. All the components will be prefabricated in the factory before transported to the construction site. The installation process is quick and easy.

Cost- effective. It will significantly shorten the construction period of your buildings, saving a great deal of time and money.

High safety and durability. The steel structure has light weight but high strength, which is also easy to maintain. It can be utilized for over 50 years.

Optimal design. The prefab steel shed can be isolated against outdoor environments as well as avoid any leak like water seepage. It also has excellent fire resistance and corrosion resistance.

High utilization. It is easy to move and relocate steel structure, which can also be recycled without pollution.

Solid construction. The steel structure fabrication shed is capable of withstanding the attack of strong winds and heavy snow. It also has excellent seismic performance.

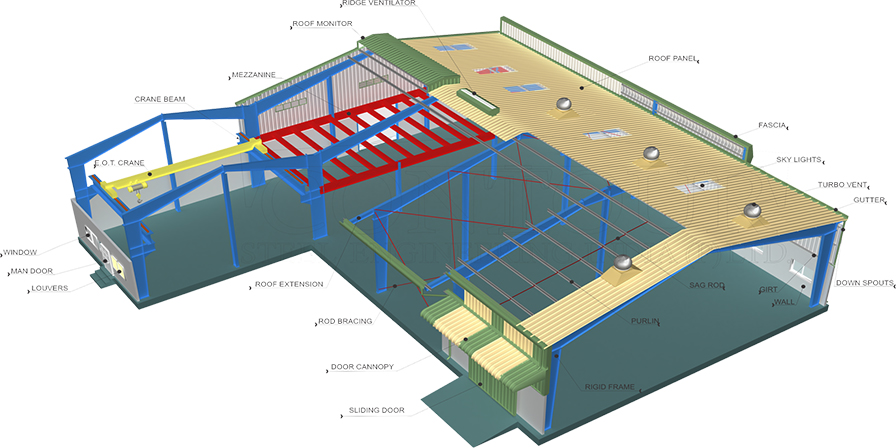

Light Steel Structure shed Design

The light steel structure shed can be designed and built into any size and shape to suit your particular needs. Here are some options for your light steel structure shed design.

Steel columns and beams constitute the main structure of steel construction buildings, which will adopt Q345B H beam. The overhead crane beam also utilizes Q345B H beam. The painting will be three layers.

Wall and roof purlin are available in C, Z, U type. Angle steel will be applied in roof horizontal bracing system. For wall column and cross bracing system, double layer angle steel will be utilized. The color of wall and roof is customized according to your requirements. The panels come in two types. One is single tile or steel tile, and the other type is composite panel, such as polyphenylene, rock wool and polyurethane. The foam is placed between the two layers of panels, making it warm in winter and cool in summer. It also has the effect of sound insulation.

When it comes to steel structure shed design, some considerations should be taken so as to make an optimal design. The consideration including but not limited to:

Impervious: to prevent seepage of rainwater from outside into metal roof panel. Generally rainwater enters into metal roof through overlapping seams or nodes. To achieve impervious function, sealing washers should be utilized in the screw mouth which will then be hidden fixed. In the overlap of panels, a sealant or welding treatment should be done to eliminate laps.

Fire proof: in the event of fire, it must ensure that the metal roof materials will not burn, and the flame will not penetrate metal roof.

Wind proof: considering the maximum wind pressure in the local area, the design of steel structure shed should make sure that the metal roof panels will not be pulled away by negative wind pressure.

Sound insulation: to prevent sound being transmitted from outside to indoors or from indoors to outside. Generally the insulation materials will be filled between the layers of metal roof panels. The effectiveness of insulation is highly related to the density and thickness of sound insulation materials.

Ventilation: considering air circulation indoors and outdoors, vents should be set on building roof structure.

Moisture proof: to prevent the condensation of water vapor in the metal roof layer. The solution is to fill the insulation wool in the layer of roof panels and paste waterproof membrane on the roof panels.

Load-bearing: the steel structure shed should has large load-bearing capacity to withstand the attack of heavy rain and snow as well as bear the construction and maintenance load.

Lightning protection: to prevent lightning from penetrating metal roof into the room.

Lighting: sunroof can be applied to improve the interior lighting during the day. It can be lighting panels or glass.

Control thermal expansion and contraction: considering some areas with large temperature difference, it must ensure that the metal roof panels will not be damaged by the stress caused by thermal expansion and contraction.

We have a variety of steel structure shed for sale, and also help you design an economical and proper solution for your needs. Looking for steel shed? Contact the sales manager online.

Construction Plan

The installation procedure of structural steel fabrication shed mainly consists of steel column installation, column bracing installation, temporary seating of steel crane beam, roof beam and bracing installation, the correction and fixing of crane beam and the maintenance of installed steel structure.

With regard to steel column installation, due to large weight and great length of columns, it is impossible to carry out one-time production and transportation. Therefore, it will adopt subsection manufacturing process, and then be assembled at construction site.

In addition, several measures should be taken during installation process to prevent the components from damage. For example, before hoisting the steel columns, a wood should be placed on the column base plate in order to avoid damaging.

How To Take Care Of Your Steel Structure shed?

There are some notes for owners of steel structure shed to maintain their buildings:

After the installation of steel structure buildings, the owners cannot change the structure and dismantle bolts or other components. If you need to change any part of the building, you must consult the manufacturer to see whether it can be changed.

The steel structure should be painted and maintained when it has been used for about 3 years so as to ensure a good-looking appearance and excellent safety.

In the use of electrical equipment, the wire and cable should be isolated by slot line pine in order to avoid electric shock accidents.

The steel structure shed should be cleaned on a regular basis.

Any damage to the surface of metal panels shall be repaired in time to prevent rain and sun from corroding the metal plate.

The maintenance of structural steel design shed has a great deal to do with the service life of the building, so the owners should pay enough attention to it.

We are professional material handling solution provider and supplies a variety of steel structure buildings, such as steel structure warehouse, steel structure shop and steel structure shed. To know more about steel structure shed, contact us now and get affordable steel shed building prices.

Product detail pictures:

Related Product Guide:

Metal Golf Cart Storage Kits: Get a Price Your Steel Building | Affordable Steel Buildings

The Persuasive Power of the Wolf Lady | Prefab Workshop

Our goods are commonly recognized and reliable by consumers and may satisfy continually developing economic and social needs for Factory Promotional Light Steel Structure Building - Galvanized Wide Span Light Steel Frame Storage Warehouse Workshop Shed – Hongji Shunda , The product will supply to all over the world, such as: Libya , Germany , Kuwait , we're now looking forward to even greater cooperation with overseas customers based on mutual benefits. We are going to work wholeheartedly to improve our products and services. We also promise to work jointly with business partners to elevate our cooperation to a higher level and share success together. Warmly welcome you to visit our factory sincerely.

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!