Hot Rolled Narrow Flange OEM Precision PEB Low Cost Processed Q235/Q345 Structural Wholesale Pre-Engineered Building

An efficiently designed pre-engineered building can be lighter than the conventional steel buildings by up to 30%. Lighter weight equates to less steel and potential price savings in structural framework.

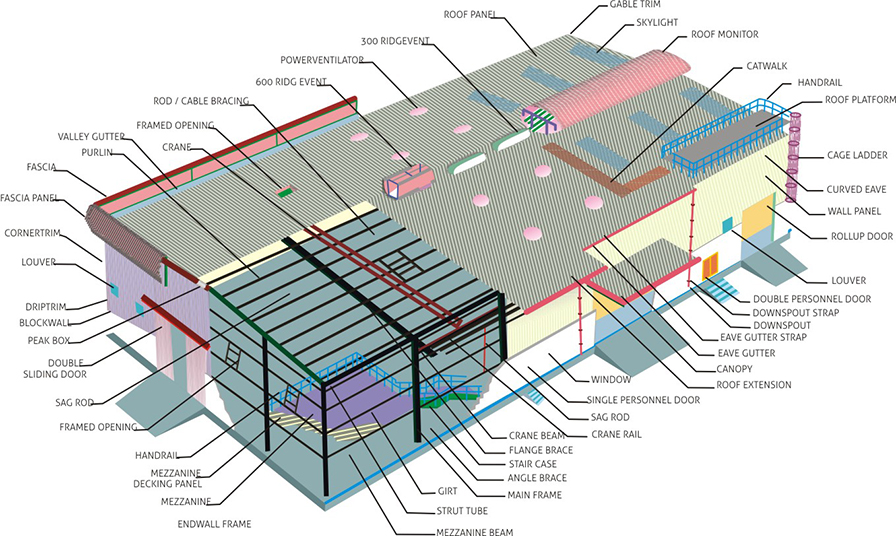

Major Components of Pre-Engineered Steel Building

The major components of the PESB are divided into 4 types-

1. Primary Components

Primary components of the PEB consists of mainframe, column, and rafters-

A. Main Frame

The main framing basically includes the rigid steel frames of the building. The PESB rigid frame comprises of tapered columns and tapered rafters. Flanges shall be connected to webs by means of a continuous fillet weld on one side.

B. Columns

The main purpose of the columns is to transfer the vertical loads to the foundations. In pre-engineered buildings, columns are made up of I sections which are most economical than others. The width and breadth will go on increasing from bottom to top of the column.

C. Rafters

A rafter is one of a series of sloped structural members (beams) that extend from the ridge or hip to the wall-plate, downslope perimeter or eave, and that are designed to support the roof deck and its associated loads.

2. Secondary Component

Purlins, Grits and Eave struts are secondary structural members used as support to walls and roof panels.

A. Purlins and Girts

Purlins are used on the roof; Grits are used on the walls and Eave struts are used at the intersection of the sidewall and the roof. Purlins and girts shall be cold-formed “Z” sections with stiffened flanges.

B. Eave Struts

Eave struts shall be unequal flange cold-formed “C” sections. Eave struts are 200 mm deep with a 104 mm wide top flange, a 118 mm wide bottom flange, both are formed parallel to the roof slope. Each flange has a 24 mm stiffener lip.

C. Bracings

Cable bracing is a primary member that ensures the stability of the building against forces in the longitudinal direction such as wind, cranes, and earthquakes. Diagonal bracing in the roof and side walls shall be used.

3. Sheeting or Cladding

The sheets used in the construction of pre-engineered buildings are Base metal of either Galvalume coated steel conforming to ASTM A 792 M grade 345B or aluminum conforming to ASTM B 209M which is cold-rolled steel, high tensile 550 MPA yield stress, with hot dip metallic coating of Galvalume sheet.

4. Accessories

Non-structural parts of the buildings such as bolts, turbo ventilators, skylights, lovers, doors and windows, roof curbs and fasteners make the accessories components of the pre-engineered steel building.

Advantages of Pre-Engineered Steel Building

1. Reduction in Construction Time

Buildings are typically delivered in just a few weeks after approval of drawings. Foundation and anchor bolts are cast parallel with finished, ready for the site bolting. In India, the use of PEB will reduce the total construction time of the project by at least 50%. This also allows for faster occupancy and earlier realization of revenue.

2. Lower Cost

Due to the systems approach, there is a significant saving in design, manufacturing and on-site erection cost. The secondary members and cladding nest together reducing transportation cost.

3. Flexibility of Expansion

Buildings can be easily expanded in length by adding additional bays. Also, expansion in width and height is possible by pre-designing for future expansion.

4. Larger Spans

Buildings can be supplied to around 80M clear spans.5.

5. Quality Control

As buildings are manufactured completely in the factory under controlled conditions the quality is assured.

6. Low Maintenance

Buildings are supplied with high-quality paint systems for cladding and steel to suit ambient conditions at the site, which results in long durability and low maintenance costs.

7. Energy-Efficient Roofing and Wall Systems

Buildings can be supplied with polyurethane insulated panels or fiberglass blankets insulation to achieve required “U” values.

8. Architectural Versatility

The building can be supplied with various types of fascias, canopies, and curved eaves and are designed to receive precast concrete wall panels, curtain walls, block walls and other wall systems.

9. Single Source Availability

As the complete building package is supplied by a single vendor, compatibility of all the building components and accessories is assured. This is one of the major benefits of pre-engineered building systems.

Applications of Pre-Engineered Steel Buildings

The major application of PESB is found in the following-

Houses & Living Shelters

Factories

Warehouses

Sports Halls ( Indoor and Outdoor)

Aircraft Hangers

Supermarkets

Workshops

Office Buildings

Labor Camps

Petrol Pumps/Service Buildings

Schools

Community centers