Leading Manufacturer for Steel Frame Prefab House - Prefabricated Auto Pre-Engineering Steel Frame Structure Building Prefab Car Garage – Hongji Shunda

Leading Manufacturer for Steel Frame Prefab House - Prefabricated Auto Pre-Engineering Steel Frame Structure Building Prefab Car Garage – Hongji Shunda Detail:

ADVANTAGES OF A STEEL STRUCTURE GARAGE BUILDING

Steel structure garage construction is the leading construction method for commercial structures. If you are wondering why, it is because steel structure garage are built to last several decades with little maintenance. There are many reasons to invest in a metal building over a typical wooden one. Here are some of the reasons why.

LOW-MAINTENANCE

Steel structure garage require a little bit of maintenance, but there is far less maintenance needed for a steel structure than for a wooden one. When you have a building built out of steel rather than wood, here are a few things you do not have to think about when considering maintenance:

Termites – There is no wood; therefore, you will not have to worry about potential termite damage.

Roofing Maintenance – The roof of a traditional wood building is made up of many asphalt shingles that, over time, due to old age or severe weather, can lead to roof leaks—causing significant damage that can go undetected for months. A roof leak is a costly repair that can be avoided with a metal roof that will last several decades with minimal maintenance.

Painting – A metal building does need to be power-washed annually to keep clean, but you can save money since you don’t need to hire costly exterior painters.

Versatility With an Open Layout

Steel structure garage can be used for many different functions, making the possibilities endless.

DURABILITY

Steel structure garage can also resist many different weather environments, including extreme weather. Steel structure garage can resist up to 170 mph winds. When it comes to protecting your assets, you can be sure that through hurricanes, weather, rain, and snowfall, your building will be protected. Steel frames are non-combustible; therefore, your building will be protected from fires.

INEXPENSIVE REPAIRS

The costs associated with home repairs or traditional wood repairs can be quite high. With a metal structure, it is simple to replace either some metal or an entire section.

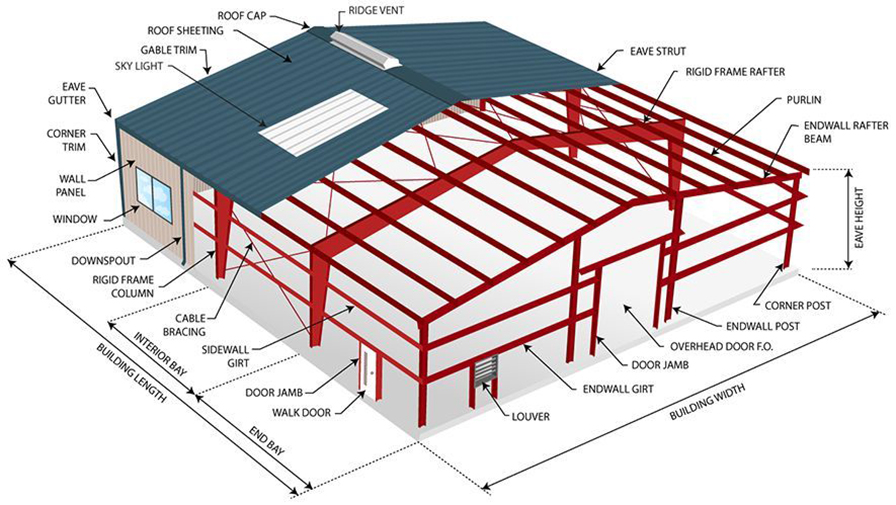

Steel structure garage is typically consisting of vertical column and horizontal beams which are riveted, bolted or welded together in a rectilinear grid. Steel beams are horizontal structural members that resist loads applied laterally to their axis. Columns are vertical structural members that transfer compressive loads. It can be used to form the skeleton of a building.

Types of Steel structure garage Construction

There are various types of steel frame construction which include:

1. Conventional Steel Structure Garage

Conventional Steel Structure Garage involves cutting steel members to the correct length and welding them to build the final structure.

This construction process may be executed on site entirely which require massive manpower.

Alternatively, for best results it can be done in a workshop partially to provide better working conditions and reduce work-time.

2. Bolted Steel Structure Garage

In this technique, all structural steel members are fabricated and painted off-site, then delivered to the construction site, and finally bolted in place.

The size of the steel structural members is controlled by the size of the truck or trailer used to deliver steel elements. Commonly, the maximum length of 6m m is acceptable for normal truck and 12m for long trailer.

Bolted Steel Structure Garage is substantially fast because lifting the steel members into place and bolting are all the works that need to be executed on construction site.

It is considered to be the most preferred construction approach because the most of the fabrication can be done in workshops, with the right machinery, lighting, and work conditions.

3. Light Gauge Steel Structure Garage

Light gauge steel is a thin sheet (commonly range between 1-3mm) of steel which has been bent into shape to form C-sections or Z-sections.

It is broadly common and used for the construction of residential and small buildings. Benefits that light gauge steel construction provide include design flexibility, high construction speed, strong, lightweight, easy to remodel, Recyclable, good Quality (durable and low in maintenance).

Applications of Steel Frame Structure

Steel frame structure is considerably suitable option for the construction of various buildings and skyscrapers due to its strength, low weigh, speed of construction, large spans construction capability.

Advantages of Steel Frame Structural Construction

Incredibly versatile

Environmentally friendly

Sustainable

Affordable

Durable

Erect quickly and easily

High strength

Relatively low weight

Ability to span large distances

Adaptability to any kind of shape

Ductility; when subjected to great force, it will not suddenly crack like glass, but slowly bend out of shape.

Product detail pictures:

Related Product Guide:

L&L lays last steel beam for Mastercard technology hub at 150 Fifth Avenue | Prefabricated Steel Structure

Winning Designs for Abu Dhabi Flamingo Observation Tower | China Steel Structure Warehouse

We insist on offering good quality generation with very good business enterprise concept, honest income as well as best and fast assistance. it will bring you not only the premium quality product or service and huge profit, but probably the most significant is usually to occupy the endless market for Leading Manufacturer for Steel Frame Prefab House - Prefabricated Auto Pre-Engineering Steel Frame Structure Building Prefab Car Garage – Hongji Shunda , The product will supply to all over the world, such as: azerbaijan , Denver , Romania , The company has numbers of foreign trade platforms, which are Alibaba,Globalsources,Global Market,Made-in-china. "XinGuangYang" HID brand products sell very well in Europe, America, Middle East and other regions more than 30 countries.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.