Light Prefabricated Outdoor Steel Roof Frame Warehouse Storage Shed

Different Types Of Steel Structure Buildings

Steel structure is commonly used to design and construct industrial factories. These factories vary in size and shape. We offer different types of steel structure factories that are built for various uses:

Steel structure shed

The steel structure shed is designed for different uses, such as to process, design and distribute materials. It features simple structure, light weight and reasonable cost.

Steel structure workshop

The steel structure workshops usually involve large and heavy equipment. They can be easily modified and strengthened for future use.

Steel structure distribution warehouse

The steel structure warehouse is designed and constructed for various purposes, such as store and distribute materials. It can be large or small based on your requirements.

In addition, we offer light and heavy steel structures to suit your project’s specifications. The former features good rigidity, light weight and convenient transportation. Besides, it is an economical option since the amount of steel used to construct wall and roof structure is less than the ordinary steel structure. While the heavy steel structure is ideal to construct various heavy industrial buildings as well as equipment support systems.

Advantages

High strength and light weight

Short construction period, low cost

Environmental friendly

Large span

Better corrosion resistance and fire resistance

Easy transportation and installation

Long service life

Custom design to suit your specific requirements

Steel Structure shed Design

When it comes to steel structure design for shed, there are several things to consider in order to select a proper solution, including:

Steel structure dimension – the required length, span and height of steel buildings.

Crane runway system – do you require an overhead crane system to be installed inside your facility?

Environmental conditions – how is the local weather conditions?

Insulation – do you require wall and roof insulation?

Main parameters of single storey steel fabrication shed structure:

Length: depending on your requirements.

Column spacing: generally 6m. It can also be 7.5m, 9m or 12m according to your requirements.

Span: generally 9-36m. It can be designed to be single span, double span or multi-span.

Height: 4.5-9m (without installing an overhead bridge crane)

When one or more overhead crane systems are required to be installed in your facility, the crane model and lifting height should be specified in order to determine the building height.

Runway system: available

Wall and roof insulation: available

The cost of steel structure shed does not include doors and windows.

The steel structure buildings can be ruggedly constructed to withstand harsh weather conditions.

Project Cases For Your Reference

A typical example falls in light single-span steel portal frame with crane runway beam. The rated load capacity of the crane is 20 tons for moderate working.

The roof structure takes the form of organized drainage in order to make a simple and good-looking façade effect.

The roof uses polyurethane panel as well as high-grade self cleaning panel in order to reduce ash accumulation and keep the roof clean. It has large bearing capacity, large span and fast drainage.

The lap joint is designed with fluid mechanics to ensure quick installation and good sealing effect.

The wall uses polyurethane panel, which has excellent heat and sound insulation as well as better appearance. It can be installed easily and quickly.

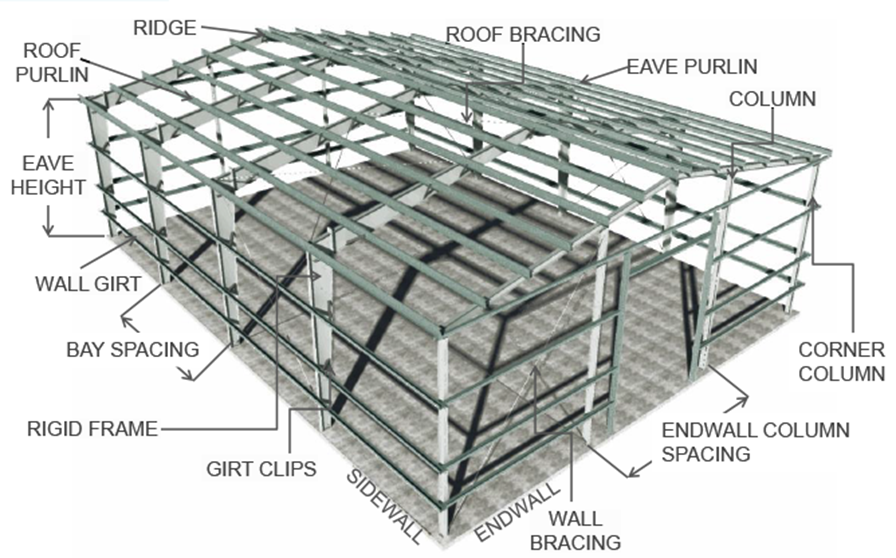

Components Of A Typical Single Storey Steel Structure shed

The steel structure can be designed with long span, clear internal space and flexible internal layouts. It has a simple structure, mainly including:

The main components: steel columns, steel beams, wind-proof columns and crane runway beam. The H-shaped steel columns can be equal section or variable section. The columns of equal section will be adopted when the building span does not exceed 15m and the column height does not exceed 6m. Otherwise, the variable section steel columns will be used. The wind-proof column is a structural component at the gable, which is mainly used to transmit the wind load at the gable. The crane runway beam installed in the upper part of the facility is used to support crane track. It is designed according to your overhead crane specifications.

The secondary components: purlins (C or Z-shaped), bracing systems (horizontal and vertical bracing). Purlins are used to support wall and roof panels. The most commonly used purlins are C-shaped, and the thickness can be 2.5mm or 3mm. While Z-shaped purlins are suitable for constructing large slope roof. The bracing system can guarantee the overall stability of building structure.

Building envelope: color steel tile, color steel sandwich panel and other cladding materials. The common thickness of color steel tile is 0.8mm or less. Generally, we use 0.5mm color steel tile. The sandwich panel specification is available in 50mm, 75mm, 100mm and 150mm.

All the main components can be pre-fabricated in the manufacturer’s shed, including pre-punched, pre-drilled and pre-welded, and then assembled and erected at the desired location. Therefore, it will significantly shorten the construction period, save money and time for you.

We can design the steel industrial building with the right features and functions to accommodate your use. These buildings can also be designed in a way that they can be easily modified and extended in order to meet the expectations of future use. To get the most competitive price of steel structure shed, give us a call or email us.