With the development of science and technology, grid structure is more and more widely used in all kinds of building structures. One of the most important reasons is the interaction between the components of grid structure, which makes the integrity of grid structure good, the bending rigidity of indoor space large and the structure very stable.And the advantages of grid not only here, today, people come to see the actual grid classification.

Classification by grid chart:

(1) The truss structure management system of cross plan includes two-way orthogonal and vertical grid, two-way oblique grid, two-way orthogonal and oblique grid and three-way grid;

(2) The quadrangular cone system includes: the quadrangular cone grid, the time quadrangular cone grid, the diagonal quadrangular cone grid, the star row quadrangular cone grid and the checkerboard quadrangular cone grid;

(3) Triangle cone management system includes triangle cone grid, time sampling triangle cone grid and honeycomb triangle cone grid;

(4) Single side folded grid

1、 High place assembly

The installation of the steel grid is carried out by the high-altitude assembly method, which is to set up the assembly support frame at the design scheme position first, and then use the lifting equipment to hang the prefabricated members of the grid to the design scheme position above by parts (or layers), and then carry out the assembly on the support frame.This method sometimes does not need large and medium-sized lifting machinery, but the use of assembly support frame is large and there are many climbing operations.Therefore, the seamless steel pipe grid connected by high-strength bolts, made of channel steel or bolt ball connection point is more suitable. At present, there are still some steel grid construction by this method.

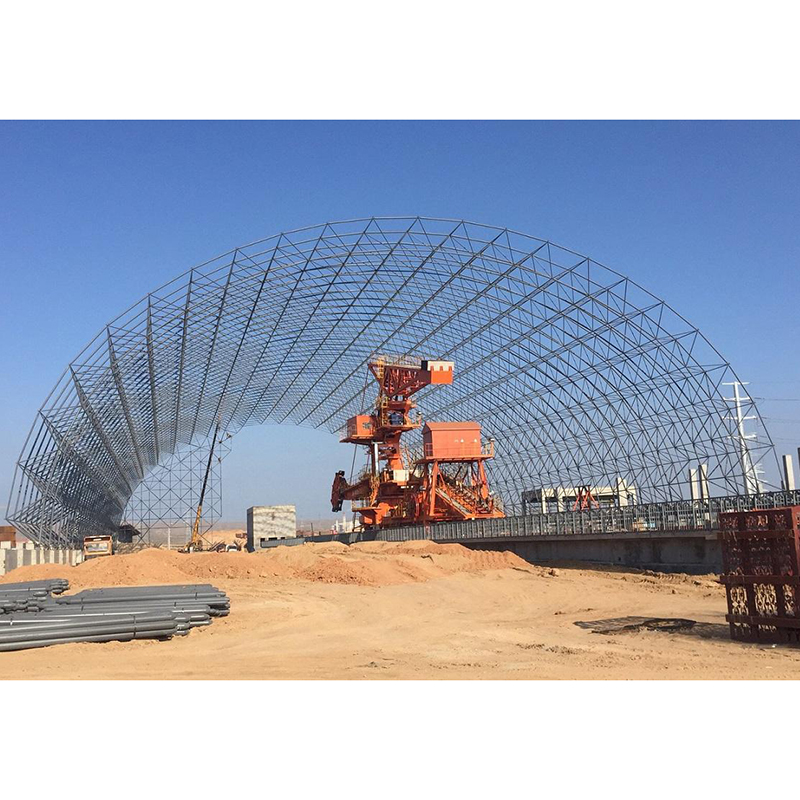

Steel structure grid

2、 Integral installation method

The integral installation method is to assemble the grid structure on the road surface as a whole, and then use the lifting machinery to improve the whole structure to the design part and fix it in many ways.This kind of engineering construction method does not need the assembly support frame of Wei’an, and the climbing operation is less, so it is easy to ensure the welding quality. However, the necessary hoisting machinery is complex in technology.Therefore, this method is more suitable for the steel grid with spherical connection points (especially for the grid with more members such as three-dimensional grid).According to the difference of common machines and equipment, the integral installation method is divided into multi machine lifting method, rod pulling method, hydraulic jack lifting method and hydraulic jack lifting method.

3、 High slip method

In recent years, the construction of steel grid roof truss by high level parallel plane sliding method is increasing gradually, especially in the cinema, hall and other engineering projects.In this kind of engineering construction mode, most of the grid structures are assembled in the cast-in-place slab on the floor of the building hall (or the assembly service platform can be set up on the viewing platform of the audience hall). After the assembly of one assembly module is completed, it is required to land on the sliding track and use the traction belt machine equipment to slide forward for a certain distance.Then two modules are assembled on the assembly service platform. After the assembly, they slide forward together with one assembly module. In this way, the assembly continues to slide forward step by step until all the grid structures are assembled and slid to the place.

Post time: Jun-08-2020