PEB Steel Structure Buildings Wearhouse Accessories Anti-Rust Carbon Steel Customized Fire Resistance Galvanized Pre-Engineered Building

The adoptability of PEB in the place of Conventional Steel Building design concept resulted in many advantages, including economy & easier fabrication. These type of building structure can be finished internally to serve any functions that is actually help in low rise building design. Examples of Pre-Engineered Buildings are warehouses, Canopies, Factories, Bridges etc.

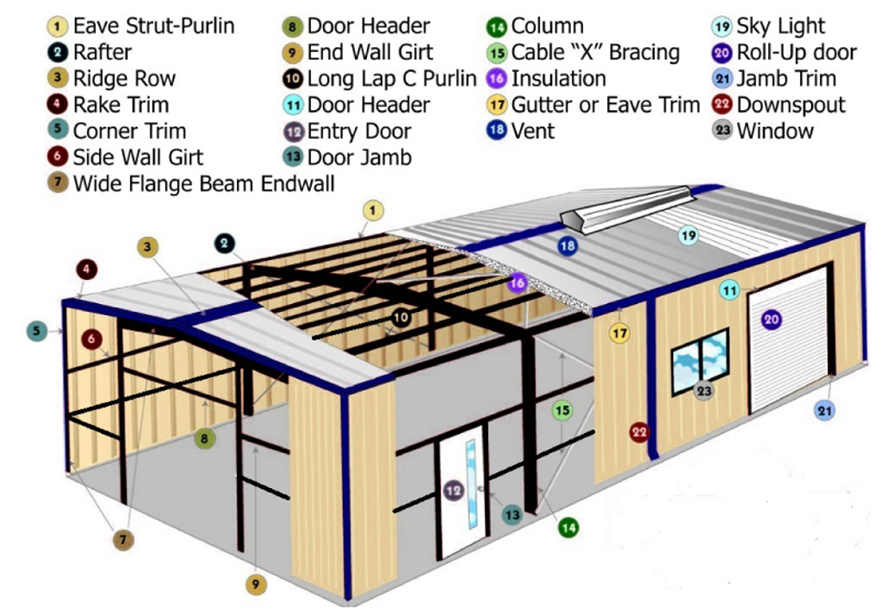

Components of PEB:

Pre Engineered Buildings consist different steel structural member which are as follows,

Primary Frame: Primary framing of a PEB is an assembly of builtup I-Shaped steel members & that framing consist trusses or castellated beams etc.

Secondary Structural Elements: It is actually Cold Formed Members, which can be in diff. shapes like “Z”, “C” etc. In general known as “Purlins”.

Roof & Wall Panels : Tin shades & Curtain Wall made of Glass & Roll-formed steel sheets usually comes in this category , S

Sandwich Panels: Sandwich Panel is made of three layers , in which a non-Aluminum Core is inserted b/w two aluminum sheet.

Other Accessories: Mezzanine floors, Bolts, Insulation, etc.

Advantages of PEB:

There are many advantages of Pre Engineered Buildings, which are as follows,

Quality control is the main advantage as all the structural member are engineered beforehand, standards of different codes also taken into consideration & these components are made in factory under the supervision of Quality Control Engineer.

Lower cost due to the saving in design, manufacturing and on site erection cost.

Minimizing time of construction due to the use of software for design of the structural components.

Low Maintenance due to use of standard quality of paints over steel members , which increases the ability to withstand & finally the maintenance cost will be low as compare to conventional steel building.

Quick Erection, as all the members are Pre Manufactured & skilled labor is used for connections of different components.

Warranty on PEB, mostly warranty period of 20 years given by manufactures for PEB.

Disadvantages of PEB:

Although PEB have many advantages in the field of Industrial structure but still there are some demerits of Pre Engineered Buildings, which are as follows,

Rusting / Corrosion Sensitive, as if the quality of steel used or paint used for coating of steel members is not of good quality , than it can damage the structure and thus reduces the life of structure.

Insulation Cost, as insulating the building to an agreeable benchmark will furthermore add to your construction costs.

Appearance, Steel Sections can be unattractive when left exposed.

Why choose PEB?

Customization

A cookie-cutter building design may work for applications such as a backyard shed or sod storage, but it’s likely a more customized structure would work better for you. Some of the customizable aspects of our pre-engineered steel buildings described below make your structure more reliable while others add functionality and aesthetic features. Either way, as you envision your new building, customizability is the difference between the perfect building and settling for the status quo.

Designed According to Use: No matter the reason for constructing your new building, there are design considerations that simply make your building more efficient and functional. Here are some instances where being able to design for a specific use is beneficial.

Customizations: Choosing the right mix of metal building components is just as important as the size and shape of your building. Adding any of the following accessories to your building order will improve the functionality of the exterior and interior of your building.

Versatility

After learning about all of the ways you can customize your building, it’s easy to conclude that this type of construction is versatile. Below is a range of applications we have supplied within each building category.

Auto Shops: The right combination of bay sizing and spacing is essential for an auto shop to generate revenue from every possible square foot.

Churches: Accounting for a stage, chairs or pews and even a fellowship area is a science. General Steel designs its church buildings to utilize every square foot of space efficiently.

Garages: Our team takes your unique combination of cars, gear, tools and other garage essentials into account when designing your garage or workshop.

Warehouses: Engineering a warehouse space to be column free ensures that every available portion of rentable or storage space is available.

Strength and Durability

For many people, a pre-engineered metal building is one of the biggest investments they will ever make, especially if it’s being used as a primary residence. Simply put, you get what you pay for and if you opt for a cheaper “economy” building you will be sacrificing the strength and durability synonymous with rigid frame buildings. The difference is in the framing and here’s what sets a pre-engineered metal building apart from the alternatives.

Enduring Storms: If there’s any question what type of building is the strongest and most durable, do a simple Internet search for storm damage. Most of the images you see of failed commercial buildings are Quonset huts, pole barns and light gauge buildings. General Steel pre-engineered buildings, on the other hand, have endured even the strongest storms time and time again as seen in this video.

Warranties: All General Steel buildings come standard with the best warranties in the industry. Your other options may come with a one-year manufacturer’s warranty, but that perils in comparison to the General’s 50-year structural, 40-year paint and 25-year Galvalume roof warranties.

Value

Consumers are always looking for the most value whether they’re buying a car, television or pre-engineered building. While rigid frame buildings are not the cheapest available option, they certainly deliver the most value. Prefab buildings often carry a higher initial investment than light gauge buildings or other building designs. At around $8-$14 per square foot, metal buildings can be out of some preliminary budgets, but it’s better to save your money. In fact, in some areas local insurance companies won’t even insure the alternatives, so you may end up replacing your building out of your own pocket. It’s better to buy once than twice and have a building that will last for generations.

Construction

Pre engineered buildings require no welding and feature all bolt together construction. Each building’s framed openings are pre-punched at the factory, making installing the customization components extremely easy.