Prefab Steel Structure Building Warehouse/Workshop/Aircraft Hangar Construction

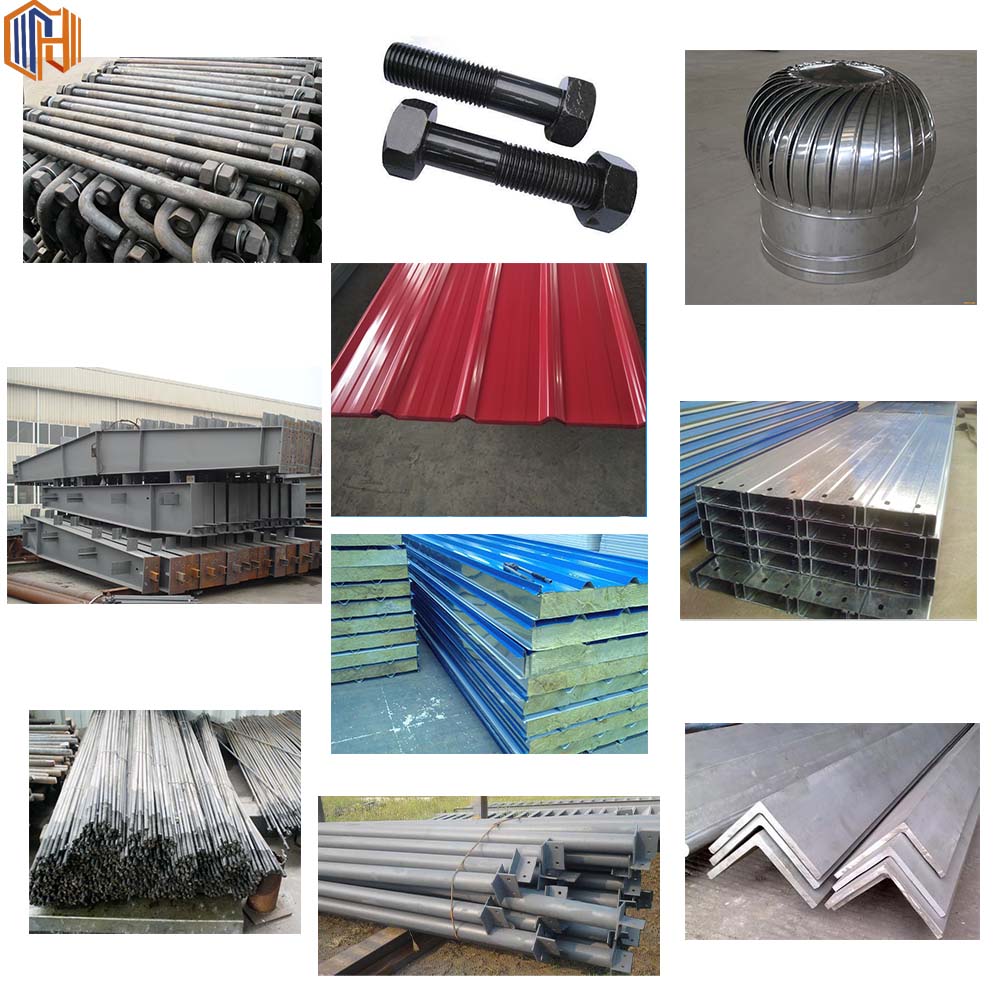

Prefabricated Steel Structure Warehouse Building Material

|

Main Steel Grade:

|

Q355 Q345 Q235 Q355B Q345B Q235B

|

|

Beam & Column:

|

Welded or Hot rolled H-section

|

|

Purlin:

|

Hot Dipped Galvanized C Z Purlin

|

|

Bolt Accessories:

|

Foundation bolt & High -Strength Bolts & General Bolt

|

|

Wall & Roof:

|

EPS /Glass Wool/Rock Wool /PU Sandwich Panel Or Corrugated Steel Sheet

|

|

Door:

|

Sliding Sandwich Panel Door / Rolling Metal Door

|

|

Window

|

Aluminiumn Alloy Window / PVC Window

|

|

Surface

|

Hot dip galvanized or painted

|

|

Other

|

Semi-transparent Skylight belts,Ventilators,Downpipe and Gutter ,Crane 5MT, 10MT, 15MT

|

|

Drawings & Quotation:

|

1) Customized design is welcomed.

2) In order to give you an exactly quotation and drawings, please let us know the building length, width, eave height and local weather. We will quote for you promptly. |

Advantages of Prefabricated Steel Structure Warehouse Building Material: steel structure warehouse

1) Cost saving and transportation convenient, custom design available steel building

2) The main beam and column are made of quality steel material Q355B Q345B Q235B steel structure workshop

3) Steel structure makes the house resist heavy wind of 180km/h and 9-grade earthquake steel structures

4) Easy assembly and disassembly several times without damage steel structure shed

5) Widely used in construction site, office building, dormitory etc. steel structures

6) Good environmental protection effect. Steel structure housing construction greatly reduces sand, stone and dosage of the ash.Most of the used materials are recyclable or degradable, little rubbish produced steel frame structure

Prefabricated Steel Structure Warehouse Building Material application: prefabricated steel structure building

Industrial steel structure :warehouse/Steel workshop/hangar/garage/chicken shed/ shed,exhibition hall, car parking agricultural storage, logistic centers

We supply completely steel structure building with Design& Engineering service: steel building, space frames, tubular steel structures, basic building elements(built-up welded H-section, hot-rolled H-section, channel, steel column, steel beam), standard frames, secondary framing, roof &wall materials, tempcon (sandwich) panels window and doors.

Payment Terms:

1) Payment: T/T(40% prepaid as deposit, balance 60% before loading) or L/C at sight

2) Delivery time: 15~40 days, as pre customers’ order

3) Shipment Loading: 20″GP, 40″GP, 40″HQ, 40″OT or in bulk

designing and detailing service for :

2. Size ( length* width* height ):_______ m* _______ m* _______ m*

3. Wind speed: _______ KM/H

4. Snow load:_______ KG/m²

5. Rain load: _______ KG/m²

6. Anti-earthquake: _______ level

7. Brick wall need or not? If yes, 1.2 m high or 1.5 m high?

8. Thermal insulation: If yes, fiberglass wool, rock wool, PU sandwich panels will be suggested; if not, the metal steels will be OK. The cost of the latter will be much lower than that of the former.

9. Door quantity & size:_______ units_______ (width)m_______ (height)m

1.Main Steel Structure

D.Floor decking: Hot dipped galvanized 688 / 750 type decking sheet

C. Steel wire / steel sheet+ Fiberglass wool roll