Top Suppliers Prefabricated Steel Structure Shopping Mall - Fabricated Industrial Galvanized Insulated Light Steel Construction Building Sheds. – Hongji Shunda

Top Suppliers Prefabricated Steel Structure Shopping Mall - Fabricated Industrial Galvanized Insulated Light Steel Construction Building Sheds. – Hongji Shunda Detail:

Multiple Types Of Steel Structure Sheds For Sale

Steel building shed can be built into a variety of sizes and styles for your practical usage. There are several options available for different applications.

Steel structure workshop building is a cost-efficient choice to build your own workshop. Compared with traditional building structure, the steel structure workshop can increase utilization of the area. Besides, the steel structure of building can realize a high utilization as it can be recycled for reuse. Thus it also exerts little hazardous impact to the environment.

When considering building a warehouse for industrial or non-industrial uses, the steel structure warehouse is a popular choice for most customers thanks to its reasonable cost, high strength and long service life. The structural steel warehouse can be found many uses in plant, commercial construction and civil usage.

Steel structure shed can be used for many projects, from commercial usage like car shed, agricultural usage like storage shed to industrial sector such as machine shop. The steel shed has flexible structure and can be installed easily and quickly.

With respect to your specific project, environmental conditions and lifting capacity of travelling crane, there are generally lightweight steel structure building and heavy duty type for you to choose from. We aim to build the best form of steel frame structure building in many aspects, including the steel structure building cost, strength, seismic and wind resistance, durability and safety. To learn more about steel structure building details, contact the sales representative online directly.

Unique Features

A basic understanding of steel building advantages and disadvantages can help you make the smartest choice. Basically, there are plenty of benefits for employing such building form.

Wide application. It is applicable to many industries and non-industries, such as manufacturing, agriculture and civil usage.

Simple construction process. All the structure parts are prefabricated in the factory, and then installed at construction site. As a result, it will greatly shorten the construction period and save costs for building owners.

Long service life. The steel building is safe and reliable, and it can withstand severe environments such as fire, strong winds and heavy rain. Besides, it requires minimal maintenance.

Delicate appearance. The steel building design is with a modern sense. The wall panels are available in multiple colors and the building structure is with high flexibility.

Reasonable cost. This building form has light weight and shot construction period, thus it can be put into operation very soon. Its comprehensive economic benefits are better than concrete structure building.

Environmental friendly. The steel structure can be recycled, and it will cause less environmental pollution when being built or removed.

High strength and reliability. The steel structure of the building has strong load-bearing capacity, excellent seismic resistance and wind resistance.

How To Make Steel Structure Building Sheds?

When it comes to steel structure design for building, it requires the clients to provide full parameters needed for their facilities such as building height, width and length. According to the type of steel, there are light steel structure and heavy duty steel structure, which will be custom designed and built to meet customer’s requirements.

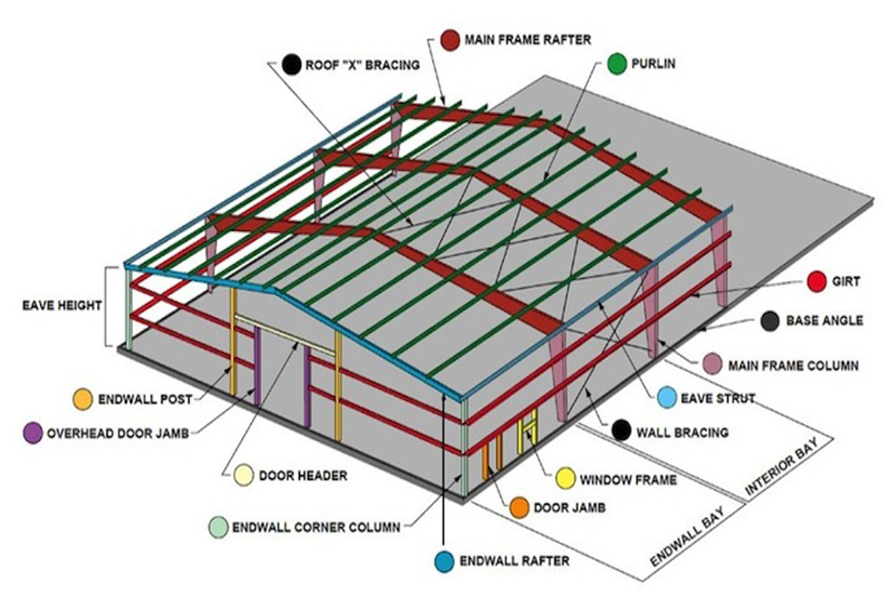

The steel structure is mainly form by steel columns, steel beams, purlin, roof and wall panels. The embedded parts serve as the building foundation. The steel columns generally utilize H-shaped or C-shaped steel, of which the C-shaped steels are connected by angle steel. The steel beams usually adopt C-shaped or H-shaped steel. The carbon structural steel uses Q235 or Q345. There are generally two options for roof panels, including steel color sheets and sandwich panels. The foam is often filled between two-layer panels, which has the effect of sound insulation. Different parts of steel buildings are usually joint by bolts.

The whole process includes:

Steel structure shed design: it will be made based on customer’s needs;

Cutting: steel plate will be cut according to drawing.

Assembly of flange plate and web plate: this process will utilize spot welding to solder two pieces of flange plates and one web plate together.

Auto welding: use arc-submerging machine to weld the whole steel structure components.

Straightening: to deform the flange and web plate to be flat.

Manual welding: to weld connection plate and purlin plate to the main steel structure components.

Shot blasting: to remove rust on the surface of steel structure.

Painting: the steel structure will be painted or galvanized to prevent corrosion.

After prefabricated in the factory, the steel structure will be packaged and delivered to the construction site, and then installed according to building drawing and manual.

In addition, there are a few considerations involved in the structural steel building design, such as seepage prevention, fire proof, wind resistance, insulation design, moisture proof and lighting designs. If you would like to make your own steel structure for workshop, warehouse or other usage, please feel free to contact us online.

How To Install Steel Structure Building?

The heavy steel structure installation procedure consists of a few main parts, including:

The site and foundation preparation.

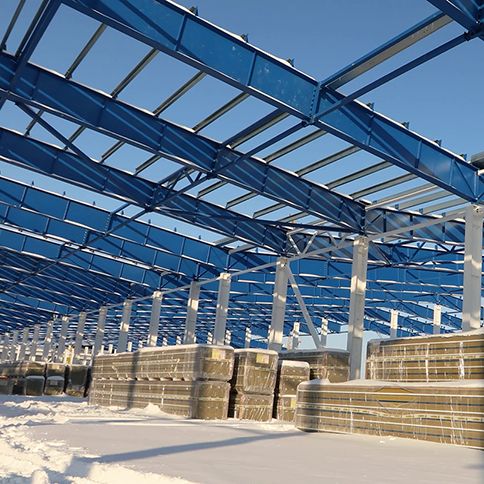

Pre-erection preparation, such as the preparation of steel materials and components for assembly.

Primary and secondary structural erection mainly encompassing the installation of rigid frame, column and beam end walls, remaining frames and wind bracing.

Insulation of roof and wall

Sheeting, such as the installation of wall panels and roof panels.

Trim, such as rake trim, corner trim and eave trim.

Installation of doors, windows and other accessories.

During the installation process, some precautions should be taken to avoid any damage to the steel structure like steel columns and beams.

The Maintenance Of Steel Building Sheds

Once it is installed, the building owners cannot change its structure privately, nor they remove any bolt or component of it. In the daily use, the owners should conduct a periodic maintenance in order to prolong the service life of the building. Generally, it can be taken into use for more than 50 years.

Under normal circumstances, it is necessary to check and maintain steel structure buildings once a year as well as take a regular cleaning. For example, we suggest you to wash dirt from the roof annually. Do not use stainless steel cleaners or plate brushes in case they scrape the surface of panels. We also urge you to remove excessive branches, leaves and snow in case they cause damage to the structural members. In the event of damage to the surface of metal structure, it should be repaired in time in case the sun and rain corrode the building. If you have any trouble maintaining or repairing your steel buildings, please contact us online.

Product detail pictures:

Related Product Guide:

Seismic retrofit of historic courthouse with precast concrete shear walls | Prefabricated Steel Structure

The Future Of Construction: Putting Innovative Ideas To Work At Autodesk’s Workshop | Prefabricated Steel Structure

Bear "Customer first, High quality first" in mind, we perform closely with our consumers and provide them with efficient and experienced services for Top Suppliers Prefabricated Steel Structure Shopping Mall - Fabricated Industrial Galvanized Insulated Light Steel Construction Building Sheds. – Hongji Shunda , The product will supply to all over the world, such as: Iceland , Congo , Kenya , our qualify products have good reputation from the world as its most competive price and our most advantage of after-sale service to the clients.we hope we can provide a safe, environmental products and super service to our clients from all of the world and establish strategic partnership with them by our professional standards and unremitting efforts.

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!